- Corporate

- Chemical Products

- Chemical Controller

- Chemical for Paint Booth

- Coil Coating

- Degreasing and Cleaning chemical

- Heat&Cool exchanger (PLATECOIL)

- Hydrophilic

- Manganese Phosphate

- Nano-coating (Pallucid)

- Rolling Oil

- Rust Preventive Product

- Stearate Soap Lubricant/Dry-in-Place Lubricant (PULS)

- Trivalent Chromium/Non-Chromium

- Zinc Phosphate/Iron Phosphate

- Processing Services

- Laboratory Services

- Articles

- What's New

- Contact Us

- Privacy Policy

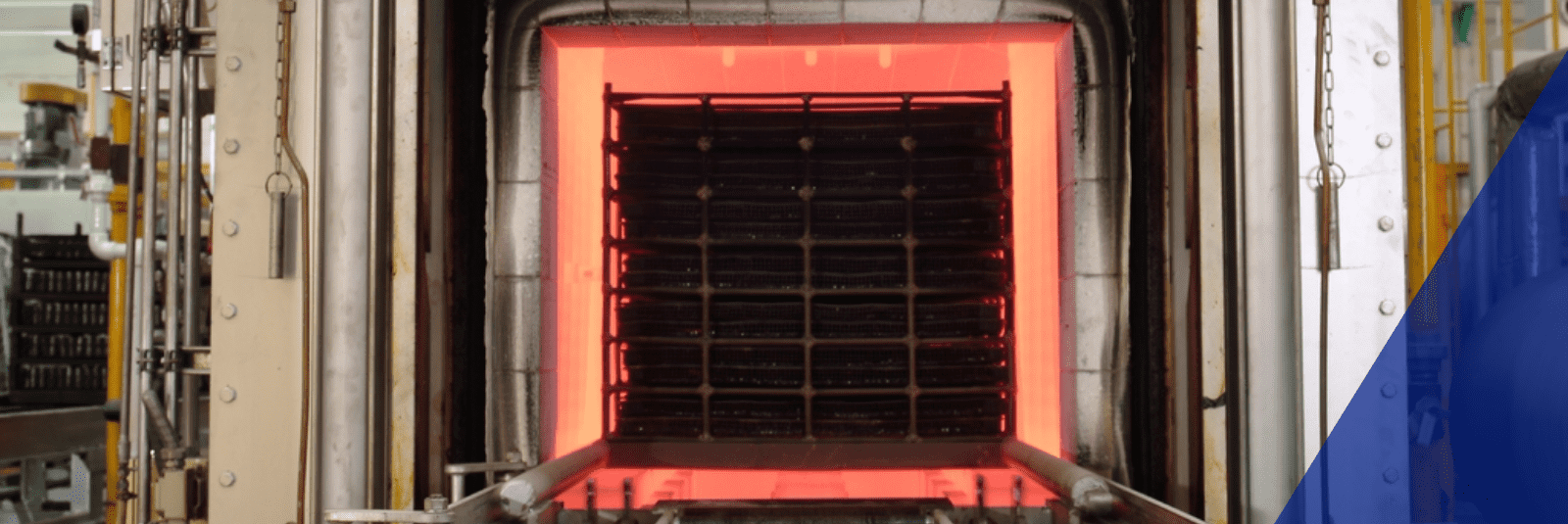

Gas Carbonitriding

Carbonitriding is a process in which carbon and nitrogen are simultaneously infiltrated into the surface of steel at a temperature of about 800oC to 880oC, lower than ordinary gas carburizing, and then quenched and hardened.

In gas carbonitriding, NH3 gas is added to a normal gas carburizing atmosphere, and nitriding and carburizing are performed simultaneously by the N component decomposed from NH3.

Since the hardenability is improved by nitriding, it is possible to treat non-alloy steel such as SPCC and low carbon steel which cannot be applied by gas carburizing, and the reduction of material cost is also a great advantage.

Since it can be quenched at a lower temperature than gas carburizing, deformation and distortion due to heat treatment can be reduced.

Characteristics

- Applicable steel type: Low carbon steel (low carbon steel such as SP material, SS material, S10C), case hardening steel (low carbon alloy steel such as SCM / SCr / SNCM)

- Quenching is possible at low temperatures, reducing quench deformation. (Excluding case-hardened steel)

- Since the hardenability is improved by the influence of nitrogen, quenching becomes easy even with carbon steel, which is advantageous in terms of quenching cracking.

- Compared to gas carburization, the abnormal hardening layer on the outermost surface is suppressed, and a uniform hardened layer can be generated.

- Improved temper softening resistance compared to gas carburizing.