- Corporate

- Chemical Products

- Chemical Controller

- Chemical for Paint Booth

- Coil Coating

- Degreasing and Cleaning chemical

- Heat&Cool exchanger (PLATECOIL)

- Hydrophilic

- Manganese Phosphate

- Nano-coating (Pallucid)

- Rolling Oil

- Rust Preventive Product

- Stearate Soap Lubricant/Dry-in-Place Lubricant (PULS)

- Trivalent Chromium/Non-Chromium

- Zinc Phosphate/Iron Phosphate

- Processing Services

- Laboratory Services

- Articles

- What's New

- Contact Us

- Privacy Policy

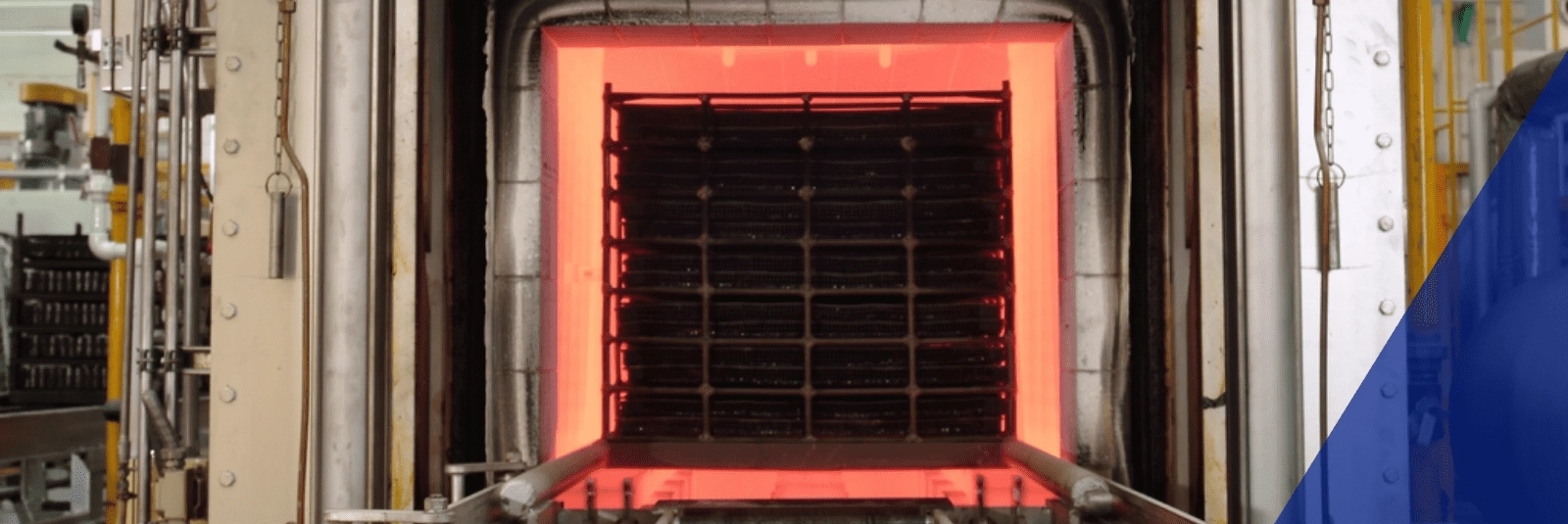

Gas Carburizing

Gas Carburizing is a method to increase surface hardness of mild or low alloy steel by heating the steel to 850oC - 940oC in an atmosphere which enriched with gas butane and propane and added to an endothermic gas (RX gas) containing CO, N2, and H2 as main components in the furnace. This is a process in which carbon is infiltrated into the surface and carburized, then hardened by rapid cooling (Quenching) at a lower temperature.

This is the most popular surface heat treatment method that has excellent strength and can usually achieve both opposing "toughness and hardness", and is widely applied to various machine parts including automobile parts and motorcycle parts.

Sometimes it is necessary to prevent carburizing on certain areas of a part. Preventing carburization in selective areas can be done with mechanical masking or chemical coating (Botan process). After case hardening, selective areas of work pieces also can be “softened” by induction tempering.

We automate these carburizing furnace production lines to build a reliable process control and a quality control system without any omissions under various conditions, and respond to customers' various QCD needs at a high level.

Characteristics

- Applicable steel type: case hardened steel (low carbon alloy steel such as SCM / SCr / SNCM)

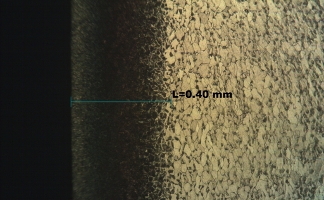

- Thick surface hardened layer can be obtained, and high toughness can be secured inside.

- Hardened layer depth and surface hardness can be adjusted as required

- Several types of quenching oil can be selected depending on internal hardness and part shape

- The surface has a light gray smooth finish (low tempering)

- Improves abrasion resistance, impact resistance, and fatigue resistance