- Corporate

- Chemical Products

- Chemical Controller

- Chemical for Paint Booth

- Coil Coating

- Degreasing and Cleaning chemical

- Heat&Cool exchanger (PLATECOIL)

- Hydrophilic

- Manganese Phosphate

- Nano-coating (Pallucid)

- Rolling Oil

- Rust Preventive Product

- Stearate Soap Lubricant/Dry-in-Place Lubricant (PULS)

- Trivalent Chromium/Non-Chromium

- Zinc Phosphate/Iron Phosphate

- Processing Services

- Laboratory Services

- Articles

- What's New

- Contact Us

- Privacy Policy

|

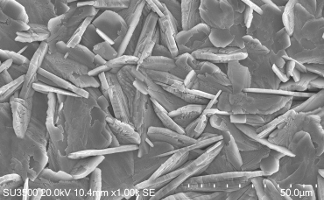

PhosphatePhosphate is a conversion process that generate phosphate crystal or film layer on metal surface, providing various properties such as anti-corrosion, adhesion, wear resistant, etc. Phosphate process also known as PARKERIZING process, PAKER process, Bond or Bonderizing, and Lubulite. Thai Parkerizing can provide various types of phosphate treatment services as follow, Zinc / Zinc-Calcium Phosphate Manganese Phosphate Chromate / Non-chromate conversion coating |

Get the info you’re looking for right now!

If you can’t find the answer you’re looking for, we’d love to hear from you – whether you’re curious about features, a sample trial, or even pricing—we’re ready to answer all questions a find the right products for you!

- Increase rust prevention and corrosion resistance properties

- Increase adhesion property

- Increase wear resistance

- Pre-treatment of cold forming process(metal soap) to lubricate and reduce friction

- Automotive parts: Camshaft, Shaft Axel, Engine Bolt, Gear, Bracket, Pin, Washer

- Motorcycle parts: Washer

- Electric appliances parts: Pore Core, Rotor Core, Pinion Shaft, Accumulator

- Electronic components: Pulley

Product type

Check more of our Product / Process type specifications below.