- Corporate

- Chemical Products

- Chemical Controller

- Chemical for Paint Booth

- Coil Coating

- Degreasing and Cleaning chemical

- Heat&Cool exchanger (PLATECOIL)

- Hydrophilic

- Manganese Phosphate

- Nano-coating (Pallucid)

- Rolling Oil

- Rust Preventive Product

- Stearate Soap Lubricant/Dry-in-Place Lubricant (PULS)

- Trivalent Chromium/Non-Chromium

- Zinc Phosphate/Iron Phosphate

- Processing Services

- Laboratory Services

- Articles

- What's New

- Contact Us

- Privacy Policy

|

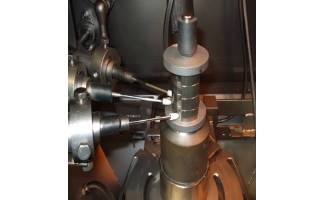

Shot PeeningTensile residual stress at the component surfaces after manufacturing processes such as milling, grinding or heat treatment process such as carburizing, carbonitriding and quenching, increase the stress during fatigue loading. This accelerates the fatigue crack initiation and increases the fatigue crack propagation rate. On contrary compressive residual stress induced over the surface of components by shot peening and leads to improving the fatigue resistance which results in delayed crack initiation and retarded crack propagation from the surface Shot peening is a cold-working process intended to produce surface deformations with the purpose of developing residual compressive stress. When impact loads on the material surface would cause the surface layer to expand laterally, the layer underneath prevents surface layer expansion, creating the compressive residual stress at the surface. Shot size is an important parameter which will effect on compressive residual stress and surface finish of a component. As shot diameter increase which will increase the magnitude of maximum compressive residual stress as well as push its location inside away from surface. As hardness of shot increases there will be increase in the value of surface compressive residual stress. |

Get the info you’re looking for right now!

If you can’t find the answer you’re looking for, we’d love to hear from you – whether you’re curious about features, a sample trial, or even pricing—we’re ready to answer all questions a find the right products for you!

- Improved fatigue strength

- Prevents cracking due to wear

- Improves tooth bottom, tooth plane strength

- Improved wear and abrasion resistance.

- Shaft Input

- Ring Gear,Pinion

- Gear Final Driven

- Ring Gear,Bevel

Frequently Asked Questions

Shot Peening is performed to increase the fatigue strength and extend the service life of metal parts, especially those subjected to high cyclic stresses or vibrations.

The main reasons for doing it are:

- Preventing Crack Initiation and Propagation: Since cracks cannot propagate in a compressive environment, the residual compressive stress layer acts as a barrier, significantly slowing or preventing the formation and growth of surface cracks.

- Converting Tensile Stress to Compressive Stress: Most fatigue cracks initiate and propagate under Tensile Stress on the surface (often induced by other manufacturing processes like grinding, machining, or heat treatment). Shot Peening replaces this surface tensile stress with a beneficial layer of Compressive Stress.

- Increasing Resistance to Stress Corrosion Cracking: The compressive stress at the surface reduces the likelihood of cracks forming in corrosive environments when combined with stress.