- Corporate

- Chemical Products

- Chemical Controller

- Chemical for Paint Booth

- Coil Coating

- Degreasing and Cleaning chemical

- Heat&Cool exchanger (PLATECOIL)

- Hydrophilic

- Manganese Phosphate

- Nano-coating (Pallucid)

- Rolling Oil

- Rust Preventive Product

- Stearate Soap Lubricant/Dry-in-Place Lubricant (PULS)

- Trivalent Chromium/Non-Chromium

- Zinc Phosphate/Iron Phosphate

- Processing Services

- Laboratory Services

- Articles

- What's New

- Contact Us

- Privacy Policy

What is EDP Coating? How Does Electroplating Work

20 December 2021

Electrochemical deposition is a technique for depositing a thin and strongly adhering layer of metal, oxide, or salt onto the surface of a conductor substrate through simple electrolysis of a solution containing the appropriate metal ion or chemical complex.

What is EDP Coating?

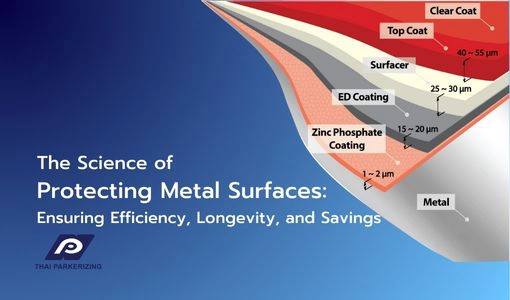

EDP, an abbreviation for Electro Deposition Painting, is a method of electromechanical surface treatment. It is a technique for achieving a smooth finish. Strong resistance to corrosion The glaze's thickness and hue are extremely uniform.

What Is Electro Deposition Plating or EDP Process Like?

Electro Deposition Painting can be divided into two main steps which are:

- Pretreatment Process

- Electro Deposition Painting Process

How Many Types of EDP Coatings Are There?

EDP coatings can be divided into two main types:

- EDP Acrylic

- EDP Epoxy

Advantages of EDP Plating

- EDP plating can produce a smooth surface and uniform thickness.

- EDP metal plating can be coated on all parts. Even the parts that ordinary sprayers can't reach.

- EDP metal plating, good rust resistance, strong adhesion, more durable than normal coating.

- The coating material for EDP plating is not easily flammable.

- EDP plating reduces hazards and has minimal to no environmental impact.

The following are some other types of electroplating.

- Continuous Plating

Continuous plating is a technique in which components such as wires, tubes, and strips are plated constantly, one after the other, in a plating assembly. The technique ensures an even dispersion of a ductile metal coating, such as aluminum, zinc, or tin, over a metal substrate, such as steel.

Surface treatment is often used to improve a metal substrate's aesthetics, wear resistance, corrosion resistance, or other surface qualities.

Precision plating utilizes a variety of electrolytes, including copper, nickel, silver, and gold-based electrolytes. Electroplating increases the metal's value since it is employed in a wide variety of sectors. Electroplating is often used to restore the appearance of worn automotive components such as bumpers, tire rims, and grills.

Due to silver's greater conductivity, it is typically utilized on brass and copper connections. Palladium and gold plating are used to coat switchgear in the telecommunications sector. - Mass Plating

Mass plating is an electroplating procedure that allows for the rapid plating of a large number of components. A barrel of components is inserted into a container filled with the coating substance to begin mass plating. The barrel is rotated to ensure that all of the barrel's components are adequately coated for corrosion prevention.

Since mass plating necessitates the use of a barrel, it is often referred to as barrel plating. The barrel is used to transport and retain the components throughout their immersion in the coating solution. Because mass plating is an electroplating technique, the barrel must be built of an electrically conductive substance; otherwise, the coating quality of the inside components may be compromised. Barrels used in bulk plating are often composed of a polymer. Within the barrel, rods and other conductors of electricity are utilized to convey an electrical charge to the internal components.

Mass plating is an extremely beneficial method for applications that demand large quantities of tiny electroplated components. While bulk plating may provide a high-quality finish, it puts pieces into touch with one another, which can have a detrimental impact on the coatings. Another kind of electroplating may be more appropriate for components that need a high degree of visual appeal. - Line Plating

Line-plated metallic structures are often employed in conjunction with one another in a processing plant or other industrial application that needs corrosion protection.

You may increase the ease with which your components move over neighboring surfaces without heating or scratching. This results in reduced wear and tear, which means they will need to be changed less often.

If you want a component to be magnetic or more electrically conductive, the appropriate plating substance may impart these features. This technology is often utilized in the fabrication of computers and other devices.

Electroplating is sometimes employed as a step between the base material and the outer coating. - Rack plating

Rack plating is a technique for electroplating fragile, big, and intricate objects that are difficult to plate using conventional methods. The components are then secured to a fixture or jig referred to as a "rack" and submerged in a plating solution bath. Metal hooks provide the necessary electrical contact while also securing the components on the rack due to the rack's ability to accommodate many components being plated concurrently.

Electroplating is used on complicated geometries that demand a one-of-a-kind finish. While saving time and money, one may employ rack plating, which can hold several components, rather than immersing individual components in a bath. Because the fixture or jig is metallic, it completes the galvanic cell circuit required for electroplating. Screws, wires, and pins provide the fewest possible electrical contacts for the plating process, resulting in a high-quality finish for complicated shapes and fragile items.

Scratches and damage are prevented during the rack plating process by properly spacing the items on the jig. However, this is a time-consuming and costly solution since it takes time to hang the components. Therefore, if the components are unsuitable for barrel plating, the only logical course of action would be rack plating. It is often employed in zinc and aluminum electroplating, where nickel and chrome are the most frequently utilized plating solutions. Before deciding on this strategy, the components' form, amount, and size should be considered.

Summary

In the automobile sector, corrosion prevention is critical. The protective layer's composition must fulfill the standards to guarantee the body's rust prevention performance, so Electro Deposition Painting (EDP) technique has gained popularity.

Thai Parkerizing, as a leader in coating, surface treatment and heat treatment technology for a wide range of purposes for customers from various industries, continues to persist in research and development to create effective solutions for customer needs.

Coating products for primer before painting, such as zinc phosphate on steel parts. The pretreatment coating performance can be checked using a Scanning Electron Microscope (SEM).

Related products

Tag :