- Corporate

- Chemical Products

- Chemical Controller

- Chemical for Paint Booth

- Coil Coating

- Degreasing and Cleaning chemical

- Heat&Cool exchanger (PLATECOIL)

- Hydrophilic

- Manganese Phosphate

- Nano-coating (Pallucid)

- Rolling Oil

- Rust Preventive Product

- Stearate Soap Lubricant/Dry-in-Place Lubricant (PULS)

- Trivalent Chromium/Non-Chromium

- Zinc Phosphate/Iron Phosphate

- Processing Services

- Laboratory Services

- Articles

- What's New

- Contact Us

- Privacy Policy

|

Zinc Phosphate/Iron Phosphate

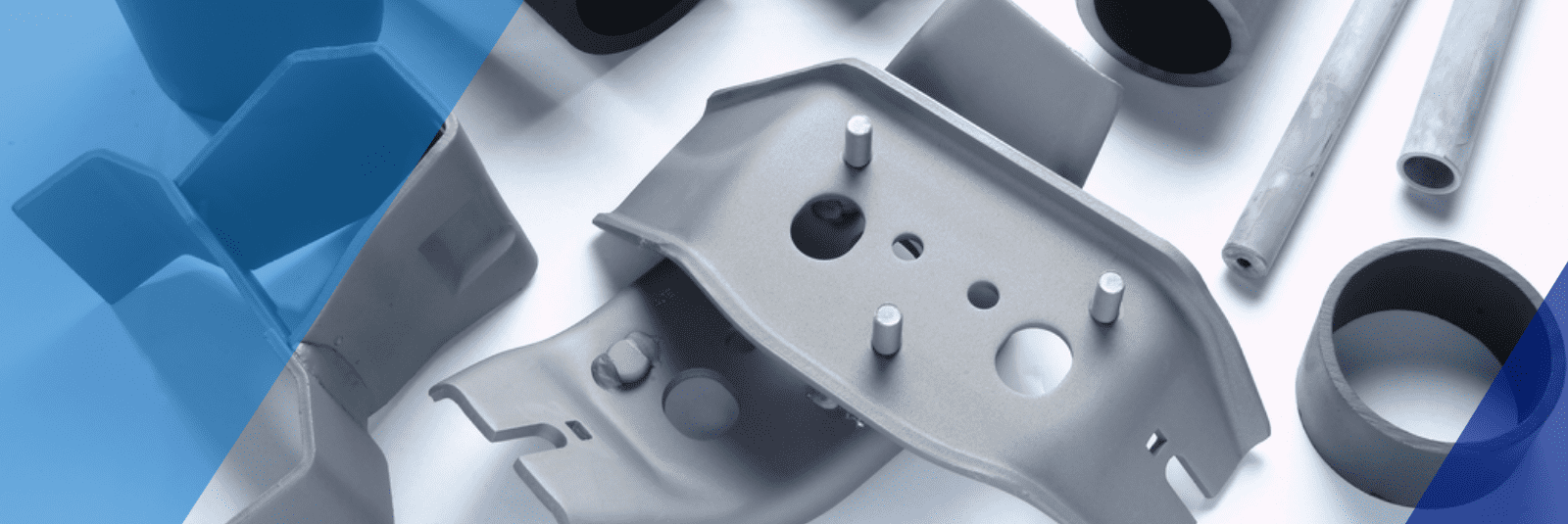

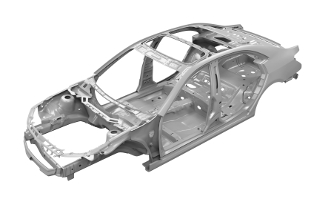

Zinc Phosphate / Zinc-Calcium Phosphate / Iron Phosphate are surface treatment chemicals that creating crystals or film Phosphate to prevent corrosion and preparing surface before entering next process such as painting, gluing, or coating with stearate soap for reducing size process. It can be applied with wide range of materials such as steel, galvanized steel, high tensile steel, cast iron, steel wire, steel pipe and aluminum. Phosphating chemicals are product that have an important role in supported the development of various industrial groups such as automotive & auto parts, electric appliances, furniture and steel industry. We intend to develop products and services to meet customer’s requirement in terms of quality, price, delivery and safety as well as environmentally friendly products with our best technology and service mind. |

Get the info you’re looking for right now!

If you can’t find the answer you’re looking for, we’d love to hear from you – whether you’re curious about features, a sample trial, or even pricing—we’re ready to answer all questions a find the right products for you!

- Increase the efficiency of rust prevention and corrosion resistance

- Being as a primer for painting and gluing rubber Increase adhesion ability

- Increase Wear resistance ability

- Helps to lubricate and reduce friction for cold forming as a pretreatment for cold forging

- Car body, Automotive Part, Motorcycle frame, Wire, Appliance part

Product type

Check more of our Product / Process type specifications below.

Frequently Asked Questions

Both methods yield good results, but they differ in quality control and application.

- Immersion: Suitable for complex geometries, allowing the solution to reach all areas. The significant advantage is better control over the crystal structure and coating density, resulting in more uniform corrosion resistance and paint adhesion.

- Spray: Increasingly used in continuous lines. However, control over the crystal structure and coating weight can be challenging.

Controlling the coating quality is paramount, with key factors to monitor.

- Surface Preparation: The surface must be perfectly clean and rinsed (Degreasing and Rinsing) to remove oil, grease, and rust. If the surface is not clean, the phosphate coating will not form uniformly, leading to defects.

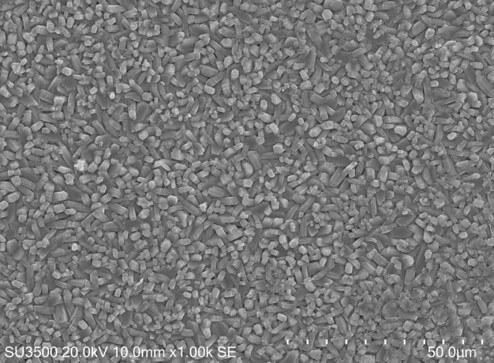

- Activation Rinse: This step is crucial for creating numerous small Nucleation Sites on the metal surface. This promotes the formation of fine and uniform crystals, which is the key to maximizing corrosion resistance and paint adhesion.

- Solution Parameters: Stable control of pH, Temperature, and the concentration of the phosphate solution (Total Acid/Free Acid) within the optimal range.