- Corporate

- Chemical Products

- Chemical Controller

- Chemical for Paint Booth

- Coil Coating

- Degreasing and Cleaning chemical

- Heat&Cool exchanger (PLATECOIL)

- Hydrophilic

- Manganese Phosphate

- Nano-coating (Pallucid)

- Rolling Oil

- Rust Preventive Product

- Stearate Soap Lubricant/Dry-in-Place Lubricant (PULS)

- Trivalent Chromium/Non-Chromium

- Zinc Phosphate/Iron Phosphate

- Processing Services

- Laboratory Services

- Articles

- What's New

- Contact Us

- Privacy Policy

How Does Rust Form? Its Types and 4 Ways to Prevent Metal from Rusting

30 August 2021

Who wouldn’t like the durability, shine and pristineness of the steel or any types of metal materials? The prominent problem is that rust is usually formed over time by the reaction of iron and oxygen in the presence of water or moisture. Rust comes in various colors, causing the corrosion to become more and more prominent over time. This article will explore how rust occurs on metal parts, and how to prevent rust effectively, what are the options?

What Exactly is Rust Chemically?

To defeat your enemy, you must know your enemy. What is rust chemically? Oxidation, the scientific name for rusting, is inevitable unless you plan on keeping your metal in space or take necessary precautions to prevent the rust from forming. The answer to what is rust chemically is simple: when you combine metal and oxygen in the presence of moisture (even the moisture naturally occurring in the air), you get rust.

Corrosion Presents in Different Types of Rust

Close-up look of rust via Envato Elements License

Rust is caused by water and humidity. But all rusts are not 100% the same. They have different colors and appearance as follows.

Red Rust – Hydrated oxide Fe2O3•H2O (high oxygen/water exposure)

This type of rust is the common rust red, the reddish brown growths of rust most people think of when rust comes to mind. It forms in very wet oxygen rich environments. The rust will spread evenly over the metal’s surface after the metal is subject to the corrosive environment for a period of time.

Yellow Rust – Iron oxide-hydroxide FeO(OH)H2O (high moisture)

Which element is necessary in the formation of rust? There’s a hint in the name of this rusting process: Iron. It is the presence of iron in your metal that causes it to rust. Yellow rust occurs in very wet environments. Because of this, it looks runny and is found in recessed surfaces.

Brown Rust – Oxide Fe2O3 (high oxygen/low moisture)

Brown rust is a very dry form of rust that’s spotty in appearance. The uneven appearance of this rust is often the result of contamination in the manufacturing process. It is flakier than the other kinds of rust.

Black scratch-like on the surface via Unsplash.com

Black Rust – Iron (II)oxide – Fe3O4 (limited oxygen)

Found as almost appearing like a black stain spreading evenly over the metal, black rust forms with an absence of oxygen. This can be caused by covering a section of the metal and reducing its contact with the air. This rust is the slowest kind of rust to form and spread.

Multiple Forms – Multiple forms of corrosion can be present at once

The same piece of metal can develop multiple forms of rust with different rust colors. A covered section can experience one kind of rust while another subject to rains forms yellower rust. Each different kind is caused by its own distinct chemical reaction.

How Does Rust Form?

Drill tools with protective coating via Envato Elements License

In this section, we will explain further about what causes rust during the usage or storage process, and find ways to prevent rust more precisely.

-

Not being stored properly.

Leaving metal out in the elements is a great way for it to form rust. What causes rust is exposure to both oxygen and moisture. Storing metals outside or in a compromised facility is sure to facilitate the formation of rust. -

Defects the manufacturing production.

Impurities and contaminants involved in the manufacturing process are also a cause of rust. These most often lead to the formation of brown rust. Because the contaminants are spread in an uneven manner, the rust it causes is spotty and irregular. This results in a dry, crust-like rust. -

No prevention of rust from forming.

Rust is inevitable if the proper steps aren’t taken. Given time, metal will rust because of the prevalence of oxygen and moisture in the air. There are, however, a wide variety of preventative measures that slow the formation of rust or prevent its formation altogether.

4 Ways to Prevent Rust from Forming

This section will explore carefully selected 4 methods to prevent rust that are easy to follow. We promise you will see a huge shift.

-

Store properly.

Proper storage is the first and easiest step for how to prevent rusting. This can mean keeping it out of the rain when not in use. Plastic sheeting or other coverage methods that reduce contact with the air and moisture will also help. Unless the storage is airtight, this method will only delay the formation of rust. -

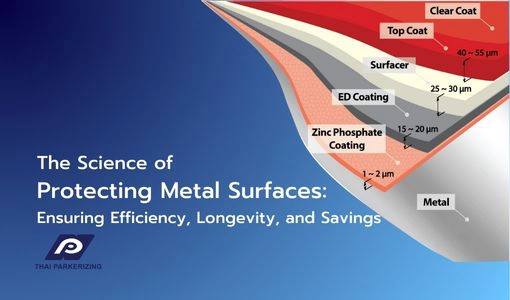

Apply rust prevention products.

There exist a wide range of coatings available to coat metal and prevent rust. Plastics, paints, even powders can be used to form a barrier between the metal and the outside world. This rust prevention coating is inexpensive and easy to apply, making it a popular choice. Coatings, however, will degrade over time and need to be cleaned thoroughly and reapplied. As they degrade, these coatings can release hazardous chemical compounds into the environment. -

Hot-dipped galvanization

Hot-dipped galvanization is just the technical term for dipping metal into molten zinc. The super-heated zinc reacts with the metal in such a way as to form its own rust-proof barrier around the metal. This is a highly-specialized process and must be performed in the proper facilities, as the fumes from the zinc can be incredibly toxic. If the metal is outside regularly it will still require some form of maintenance due to regular zinc wear. -

Cathodic protection

This type of protection is used for active (performing some function) installations that are going to be exposed to the elements for a long period of time. Preventing rusting with an electrochemical process, cathodic protection can seem complicated but is easily broken down. An anode, a more active metal than what you're looking to protect, is attached to the metal you care about and takes the rust instead. This so-called "sacrificial" anode rusts rather than your valuable pipeline.

Read More about "sacrificial" anode: What is Cathodic Protection? How Does Cathodic Protection Work?

Conclusion

Rust is an inevitable chemical reaction, but you can still prevent rust on metal. It is possible to forestall or outright prevent the formation of rust in all its various appearances. Whether it's a simple covering or a highly technical process, engineering can triumph over nature.

Thai Parkerizing, as a leader in coating, surface treatment and heat treatment technology for a wide range of purposes, including customers in the automotive parts industry, continues to persist in research and development to create effective solutions for customer needs. Our wide range of products and services include a variety of rust preventive products also presented below.

Related products

Tag :