- Corporate

- Chemical Products

- Chemical Controller

- Chemical for Paint Booth

- Coil Coating

- Degreasing and Cleaning chemical

- Heat&Cool exchanger (PLATECOIL)

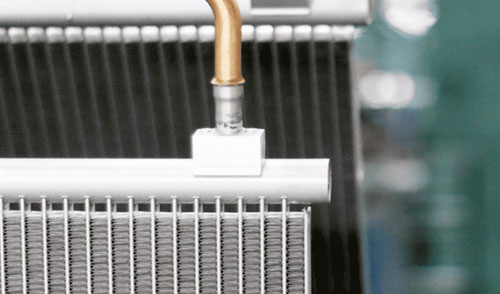

- Hydrophilic

- Manganese Phosphate

- Nano-coating (Pallucid)

- Rolling Oil

- Rust Preventive Product

- Stearate Soap Lubricant/Dry-in-Place Lubricant (PULS)

- Trivalent Chromium/Non-Chromium

- Zinc Phosphate/Iron Phosphate

- Processing Services

- Laboratory Services

- Articles

- What's New

- Contact Us

- Privacy Policy

Surface treatment

Surface treatment is a necessary step in the manufacturing process of many products. It aims to protect products, especially made out of metal, from rust, corrosion and to prolong the product’s lifetime. The most common surface treatments are coating, painting, and plating. Coating is the process of applying a thin film of material to a surface. Painting is the process of applying a layer of paint to a surface. Plating is the process of coating a metal with another metal. At Thai Parkerizing Co., Ltd., we provide many types of surface treatment services and products to fulfill the requirements of our clients. Also, we are pleased to give you some advice about which types of surface treatment that is suitable for your products. Anyways, if you want to learn about them by yourself before, you can read this article to get to know more about Surface Treatment!

Purpose of Surface Treatment

The surface of a material can be improved to make it more suitable for a specific application. So, surface treatment is a method to change the surface of a material to enhance its properties.

The purpose of surface treatment is to increase corrosion resistance, adhesion property, strength, hardness, and wear resistance. Other reasons are increasing the electrical conductivity, increasing the thermal conductivity, and other desirable characteristics of products for clients' needs.

Surface treatment can be done through a variety of methods. Each method has its advantages and disadvantages, so it is important to select the right one for the job.

Types of Surface Treatments

Surface treatments are used to improve the appearance and performance of a substrate. There are many different types of surface treatments as follow:

1. Electroless Nickel Plating (KANIGEN®)

This is a kind of plating or the process of coating Nickel on another metal without utilizing electricity. It is also shortly called EN Plating. KANIGEN® is the trademark of Electroless Plating in Japan by Nihon Kanigen (Group Company of Nihon Parkerizing, which established Thai Parkerizing Co., Ltd. in 1997) Kanigen is a result of combining these three words: Catalytic ((C)Ka), Nickel (Ni) and Generation (Gen)

Electroless Nickel plating or KANIGEN® is metal deposition by a controlled chemical reaction. The result is that the coated product has an even and smooth surface, high hardness, and high anti-corrosion ability. This process usually applies to complicated shape products.

2. Hydrophilic

Hydrophilic coating is a coating process with special chemicals that can protect products from rust and suppression a stink caused by bacteria or mold. This process usually applies to cooling coils in automobile and home air conditioner systems.

3. Phosphate

Phosphate is a conversion process that generates a phosphate crystal or film layer on a metal surface. Phosphate process is also known as PARKERIZING process, PAKER process, Bond or Bonderizing process, and Lubulite. Thai Parkerizing provides various types of phosphate treatment services as follow,

- Zinc / Zinc-Calcium Phosphate

Zinc phosphate is an inorganic chemical compound consisting of Zinc, Phosphorus and Oxygen with the chemical formula Zn3(PO4)2. It is commonly used as a corrosion inhibitor, paint adhesion, and rubber adhesion when applied to metallic surfaces. - Manganese Phosphate

Manganese phosphate coating is most commonly used within engines, transmission systems and gear to improve adhesion, corrosion protection, and wear resistance of material surface while having a low production cost. - Chromate / Non-chromate conversion coating

Trivalent chromate / Non-chromate conversion coating for aluminum is used to convert the surface properties of the substrate by nano amorphous film. This coating provides outstanding conversion resistance and is a primer for paint, lacquer, or rubber bonding.

4. Solid Lubrication (Pallube)

Pallube is the Solid lubricant coating process of NIHON PARKERIZING group company. Pallube or Solid lubricant is a coating as a thin film on surfaces that can be used to increase wear resistance and reduce friction between two surfaces without collecting dust. The coating can increase heat resistance and electrical conductivity properties.

5. Zinc Flake (DELTA-MKS®)

A coating of Zinc flake is a ‘paint’ made up of a lot of little flakes, which primarily protects components of various types from corrosion. Delta-MKS® is a Zinc flake or Zinc-Aluminum flake system of cathodic protection without Chromium (VI). DELTA-MKS products are divided up by base coats, top coats and their features, plus possible application techniques and areas of use or markets.

FAQ's

Surface treatments are a group of treatments that are applied to the surface of a material to change its surface properties. There are many different surface treatments, and each one is used for a different purpose.

When it comes to surface treatments, there are a few different materials that can benefit from them. The most common things that you can think of are the products made from metal. They can be parts of automobile, motorcycle or electric appliances. Besides, the solid lubrication process or ‘Pallube’ can be applied more on other materials, such as, resin and rubber. By doing the surface treatment process, you can improve the appearance of the material, make it more resistant to corrosion or scratching, or even improve its grip.

Benefits of Thai Parkerizing surface treatments and functional coatings services

If you are considering doing surface treatments at Thai Parkerizing, you are at the right place! With long experience in the heat and surface treatment business, Thai Parkerizing Co., Ltd. provides professional and various surface treatment services as above. We are a leader in surface treatment, rust preventive, and heat treatment business which have constantly attended to the research and development, focusing on environmentally friendly technology to fulfill all requirements of our client. You can be sure that you will receive a quality product because it will be analyzed by our efficient laboratory test before returning back to you.